- Leading steel rolling mill rolls manufacturers in India

- Manufacturer & Exporter of Industrial Chilled Rolls, Rolling Mill Machineries & Industrial Machineries

Rolling Mill Machineries

Page-03

Gear Couplings

Our clients can avail from us a range of gear couplings for hot roll steel plants. Fabricated using finest grades of EN forged steel, these are available in the size range of 106 to 118 and are suitable for 6" to 36" PCD rolling mills. We even custom make these couplings as per the client’s specific requirements.

Salient Features:

1. Takes possible misalignment of shafts

2. Ensure low power consumption

3. Tested material

Automatic Cooling Bed

Our range of W channels / Twin channels offers perfect solution for bar handling at cooling bed. These channels are used to collect the TMT bars leaving the Quenching boxes after being sheared by the Flying Shear in two strands. The channel consists of CI central box, water cooled to prevent warping during rolling, and C-type CI channels which are suspended from a longitudinal structural.

Salient Features:

1. Supporting arrangement for the twin-channel and drive system.

2. Cam device for opening closing of the pipes.

3. Hydraulic Drive for operation of the cams.

Hot End Cutting Machines

Our end cutting shearing machine incorporate latest technology for increased productivity. These machines are used in hot steel rolling mill plants for cutting of end of the angle. The processed curving edge can be trimmed by the square roller from the top and bottom at the same time, the straight line can also be trimmed by the linear gauge from the top and bottom at the same time with fine brightness and smoothness. End cutting shearing machines are installed near the roughing stand and can be used on oval stand or finishing stand.

Salient Features:

1. These machines are used to cut hot steel bars, Clutch can be provided on special order.

2. These machines are horizontal/vertical as shown in photo.

3. These machines are also of steel body with four steel gears.

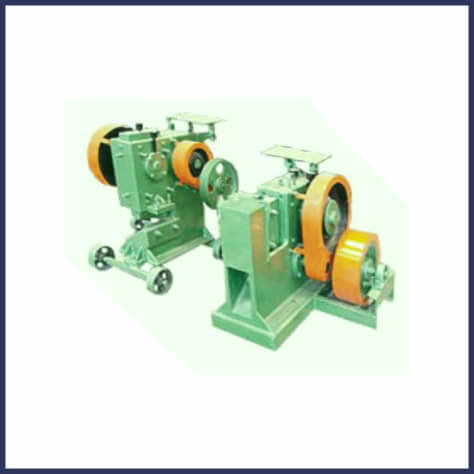

Rotary Shearing Machines

Rotary shearing machines are used between roughing and intermediate finishing stands to crop front and back ends in TMT Bars/Wire Rod Mills. These machines are provided with self lubricating drive gear box for consistent and smooth operation. We offer high performance rotatory shearing machines both fixed as well as swivel arrangements.

Salient Features:

1. Fully Automatic with pneumatic controls, capable of cutting hot ends (front and rear) During Rolling, and fixed Lengths of finished bars.

2. Steel Fabricated body.

3. Circular Blades manufactured from High carbon, high chrome steel.

E.O.T. CRANES

'Overhead cranes or EOT Cranes are also called bridge cranes, are cranes with a hoist traveling along the bridge between parallel runways. They are designed to meet the medium to heavy industrial lifting requirements, covering all parts of manufacturing process. We offers a widest & most sophisticated Customized EOT Cranes Ranging From 200 kg to 250 Tons. Our EOT Cranes are widely used in Steel Mills, Heavy Processing & Service industry for easy material handling & lifting solutions. Our EOT cranes are perfect for crane lifting operations, logistics & drive solutions for light & heavy engg. industries, processing plants, automobiles, solutions for companies of all sizes & in all sectors, trades, industries , workshop requirements in warehouses as well as in open storage areas. Our EOT Cranes are provided with great flexibility in allowing the very precise positioning and jerk-free handling of loads for smooth placing & lifting.